The most Common Typical Problems With Stihl 4-Mixes

Stihl the brand has now effortlessly established a standing reputation amongst the customers. Every time you go to a retailer to purchase a spare part for your equipment, a hedge trimmer, a chainsaw, or any other machine, the first product they will present you with will be manufactured by Stihl.

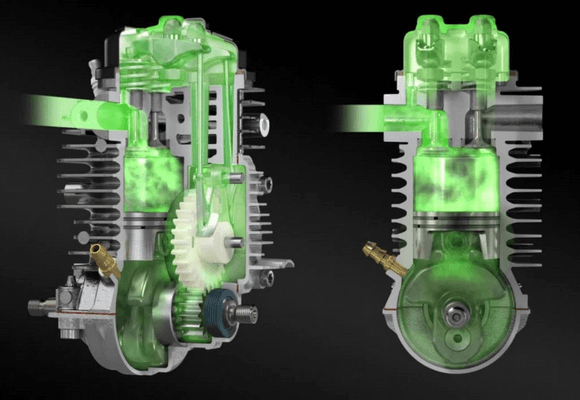

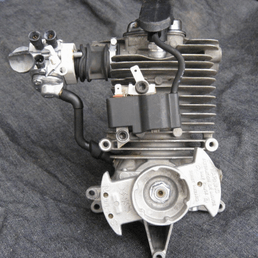

Recently the company introduced its award-winning 4-mix engine into the market, and suddenly it has become every user’s ultimate choice.

This 4-mix engine has been designed precisely to run on a mix of petrol and oil, alongside combining the advantages of a two-stroke and a four-stroke engine, delivering it all in one.

Additionally, the engine has massive lugging power and torque with a high perceptibility and numerous other benefits, such as fewer fuel emissions, lightweight, and a low threshold for noise.

But this does not mean that the stihl 4-mix is not susceptible to problems because it is. Let’s find out some common stihl 4-mix issues that users face recurrently.

Stihl 4-Mix Problems & Troubleshooting

Multiple problems can arise with using a Stihl 4-mix. Where the engine is dedicated to delivering efficiency, often and at times, it puts the user in an inconvenient situation where they have to reside to troubleshoot to problem solve the occurring issue.

Some of the typical issues that users have faced and reported will be discussed in brief detail in this section of Stihl 4-mix problems.

Problem: Delivery Issues With Fuel

Out of all the issues that customers have complained about, the Stihl 4-mix problems, the one that has taken the lead, have been with delivery issues with fuel. A problem with fuel delivery will only be raised when the problem is by your side. Otherwise, it won’t.

Most of the time, users forget that the Stihl 4-mix engine is an engine that does not only require petrol but the correct composition of petrol mixed with oil.

Owners of the 4-mix tend to be negligent with mixing both the constituents and end up mixing both the petrol and the oil disproportionately, so the fuel gets contaminated within the engine.

Such contamination of fuel should not occur. This is because when the fuel is not rightly mixed, the Stihl 4-mix engine will not power your machine. Every time you pull at the pull cord to get the machine up and running, it will be problematic, and often the engine will start only to lapse mid-operation.

Additionally, the issue with the delivery of fuel can also significantly and adversely impact the carburetor inside the machine and ensure the lifespan and durability of the 4-mix engine are shortened.

Troubleshoot

If you are looking to avoid the problem of the delivery issue with fuel in your Stihl 4-mix engine, be cautious when mixing the ratios of oil and petrol to form a mixture to be later added to the tank of the machine.

However, despite efforts, if you still cannot formulate a suitable composition, try to look for an alternative- a ready-to-be-installed mixture of fuel and oil in the market.

Problem: Engine Does Not Start

As we stated in the earlier concern, the engine would not start when there will be an inaccurate mixture of oil and petrol. Another reason the engine is not starting is the fuel, but in this situation, the added fuel to the Stihl 4-mix has been contaminated.

Contamination of the fuel only occurs when the fuel stored in the engine’s tank has been accidentally mixed with water. This problem with the fuel getting mixed with water will likely arise with those users who use their 4-mix engine machine in landscapes.

For example, people, without taking notice of the wet landscape, continue to use their land mowers or weed eaters on the ground to finish their tasks. Sometimes the water on the landscape starts seeping into the engine, contaminating the fuel.

Even though the amount of water that seems to go into the engine tank is not a lot and is only a minute amount, it is enough to contaminate the fuel and cause problems with the stihl 4-mix not starting.

Another way fuel can be contaminated is when people pour water over their engines to stop them from running. Although the water gushing does get the engine to come to a halt immediately, the water, too, goes into the engine’s fuel tank.

Troubleshoot

The extremely convenient way to ensure that the engine’s fuel does not get contaminated and you do not have to suffer with the engine not starting is to stop pouring water over the engine to bring it to a stop. Secondly, try and avoid using a machine containing a 4-mix engine over any wet area or greenery.

Problem: Intensified Compression

Most customers complain about the engine being hard to pull at, which causes them trouble with starting their machine. The only reason the Stihl 4-mix gets challenging to pull is when the engine’s compression has intensified.

Primary reason for the enhanced compression materializing is due to the adjustment of the valve. Users do not notice how much they adjust the valves and, at times, without regard for it, end up tightening the valves to an extent where the compression increases and the engine gets difficult to pull at.

Therefore, maintaining the engine’s valves is very important for your engine to run. If you continuously keep adjusting the valves, tightening them, this phenomenon can negatively impact the camshafts too.

The intensified compression and utilization of the machine in hot temperatures can cause the camshafts made out of plastic to wear out or melt. When this starts to happen, the camshafts will stop responding to opening to release the compression, allowing the compression to build up within the engine.

Troubleshoot

A preventive measure to avoid having intensified compression in the engine is always to adjust the valves per the requirements of the machine. You can easily find the instructions for adjusting the valves on the manual guide with your purchase.

Then with the use of the manual guide and with the help of the guidelines, adjust the valves to an extent whereby the compression is not enhanced, nor does it affect the camshafts.

Problem: Clogging of Tank Vent

Tank vent is a crucial component and the one without which the fuel will not be successfully delivered to the engine. Purpose of having a tank vent in the 4-mix engine is to allow the fuel to be in combination with the atmosphere.

The component permits the air to move in and out of the tank for fuel so that the pressure within the tank can be equalized with the pressure existing outside the tank.

Supposedly in a scenario where the air cannot go outside the fuel tank, the pressure will keep building up within, which can potentially lead to spills and damage to the tank, which can be hazardous.

Reason, why the tank vent of the 4-mix engine gets clogged is again because of the user’s negligence. Some users end up overfilling the tank when adding fuel into the tank. This does not leave any space in the tank for the air to adjust itself and eventually clogs the vent.

Troubleshoot

Clogged vent in the 4-mix engine is never a good indicator. The 4-mix clogged tank cannot only cause the added fuel to overflow and leak through the machine but also impact the engine.

Therefore, as a user of the 4-mix engine, you must always be aware of the amount of fuel you add to the machine. This is because even a slight overflow of the fuel than usual can result in clogging the tank vent and disrupting your operations majorly through the engine not starting.

Frequently Asked Questions

Yes stihl 4-mix engine is one of the best engines manufactured to this day.

No problems with the 4-mix are easily avoidable, and you can do so by following the recommended troubleshooting options.

Yes, you can quickly fix problems with the stihl 4-mix. If you have any of the stated problems, follow the recommended troubleshooting.

Conclusion

As we have observed in this article that most of the stihl 4-mix problems are the ones that arise out of users’ negligence. It, therefore, implies that the engine in itself is not a flawed product. Thus, to avoid these problems, be more cautious using the stihl 4-mix.

In sharing his knowledge, Brayden aims to guide individuals and professionals alike through the complexities of managing land and effectively using machinery. His insights are practical, borne out of hands-on experience, and cover a spectrum of scenarios in land management. More about me